Home > Skived Fin Heat Sinks

Skived Fin Heat Sinks

Skiving is a manufacturing process where thermal solutions are formed by shaving one solid block of copper or aluminum into a finned heatsink. This method eliminates the resistance layer that is present with the solder layer in stacked fin heatsinks since skived fins are built from a single piece of metal. Skived fin heatsinks also require minimal tooling charges, which makes it a cost-effective solution. Skived heatsinks can also be customized with embedded heatpipes to add a performance boost if needed.

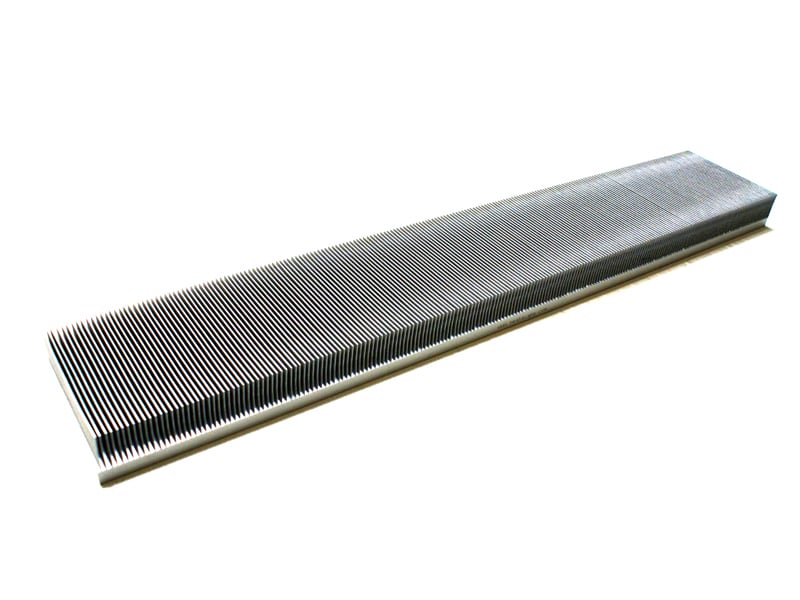

Large Footprint Skived Heatsink

Large scale skived fin heatsink used for industrial application. over 1 meter long!

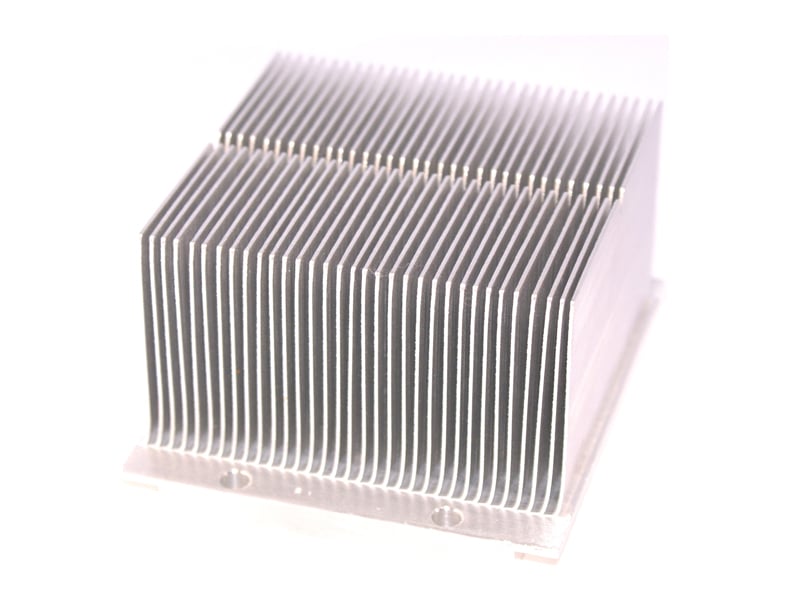

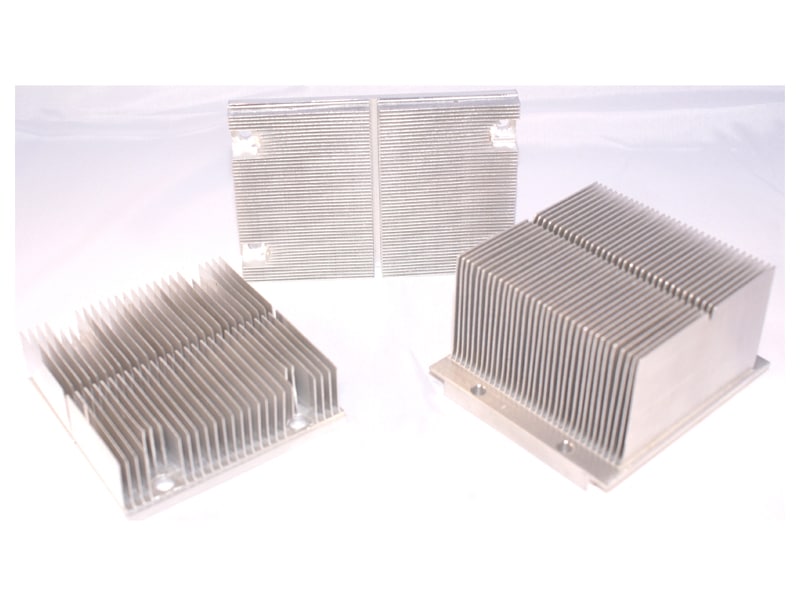

All-Aluminum Skived Heatsink

Aluminum skived heatsink with 2" tall fins can be an efficient substitue for extrusion parts

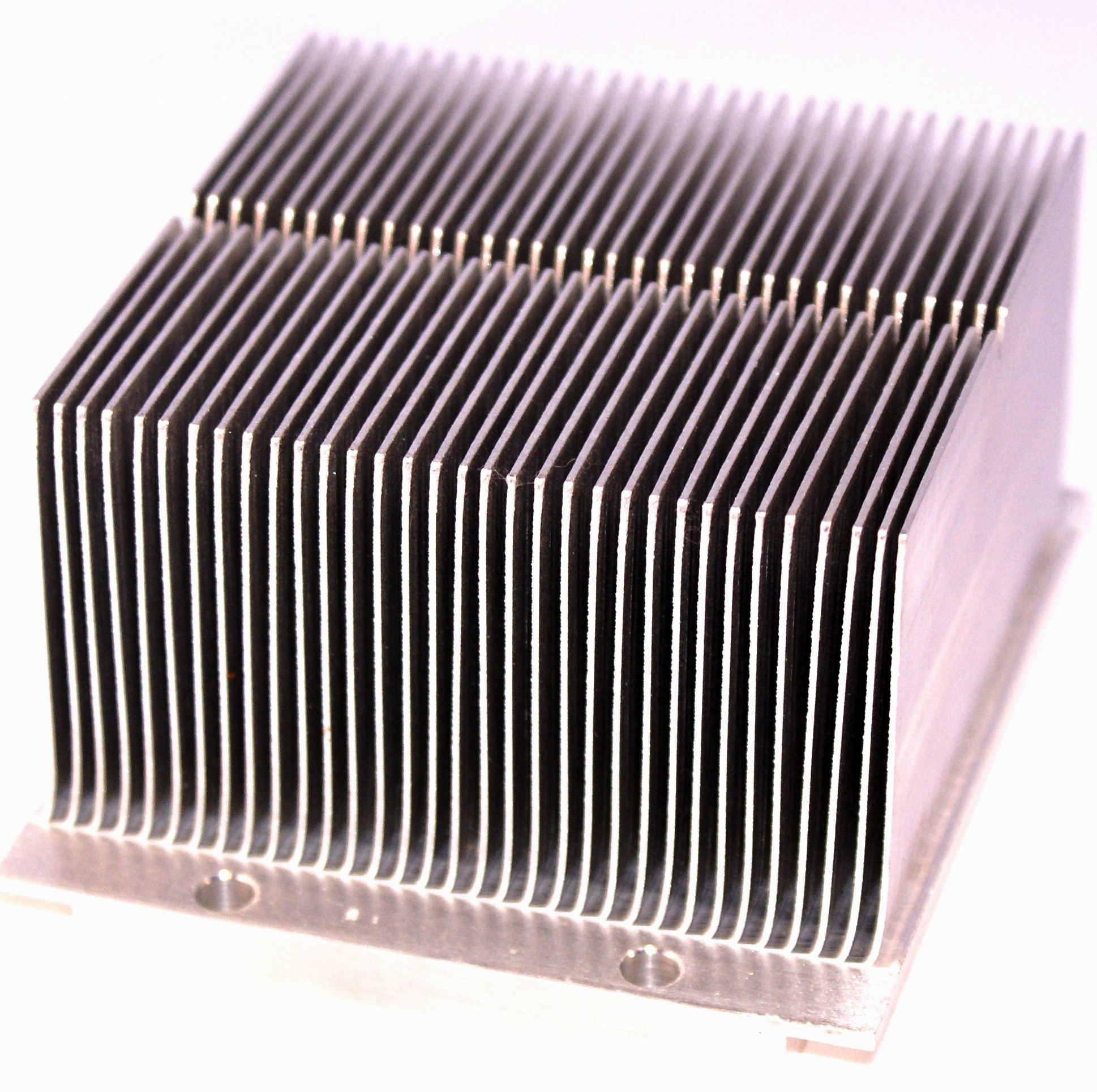

Low Profile Skived Fin with Groove

Machined features can be added into the fin region of a skived part to compensate for clearance issues, clip grooves, mounting features...etc.

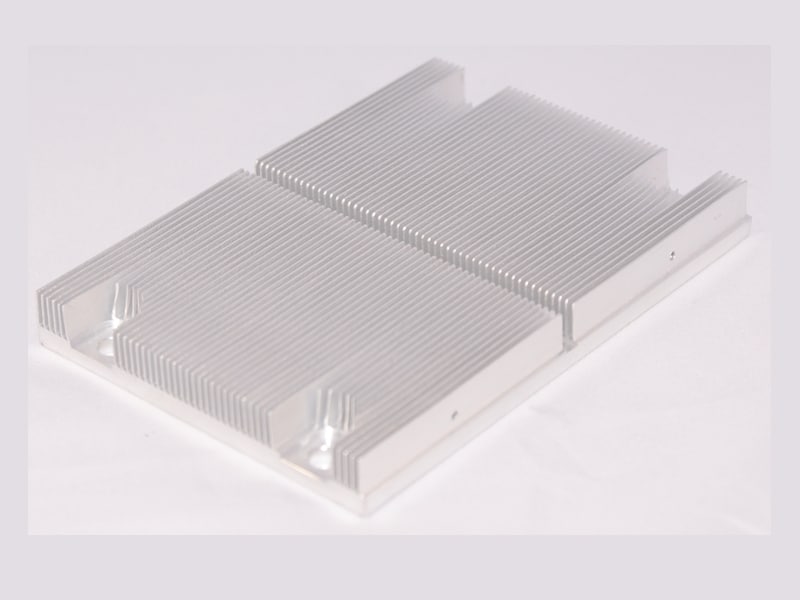

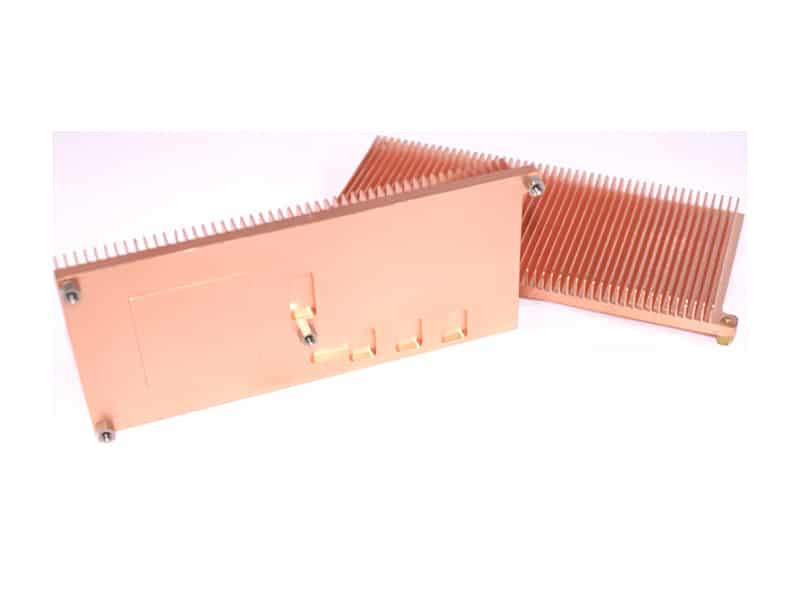

Machined Features into Skived Fin Base

Complex machining features such as clearance pockets, heatpipes grooves, clearance holes...etc. can be milled into the base of these skived fin heatsinks

Family of Skived Fin Heatsinks

Trip of Aluminum Skived parts with various skiving features